Production Planning & Control

Considering the special features of process planning and production control in different industries, custom software produced in accordance with the requirements of each industry, is essential for success in projects of planning. Therefore, in order to learn more, in the following, has been presented sample images of software systems and System catalog.

Production management also called operations management, planning and control of industrial processes to ensure that they move smoothly at the required level. Techniques of production management are employed in service as well as in manufacturing industries. It is a responsibility similar in level and scope to other specialties such as marketing or human resource and financial management. In manufacturing operations, production management includes responsibility for product and process design, planning and control issues involving capacity, quality, organization and supervision of the workforce. Production management’s responsibilities are summarized by the “five M’s”: men, machines, methods, materials, and money.

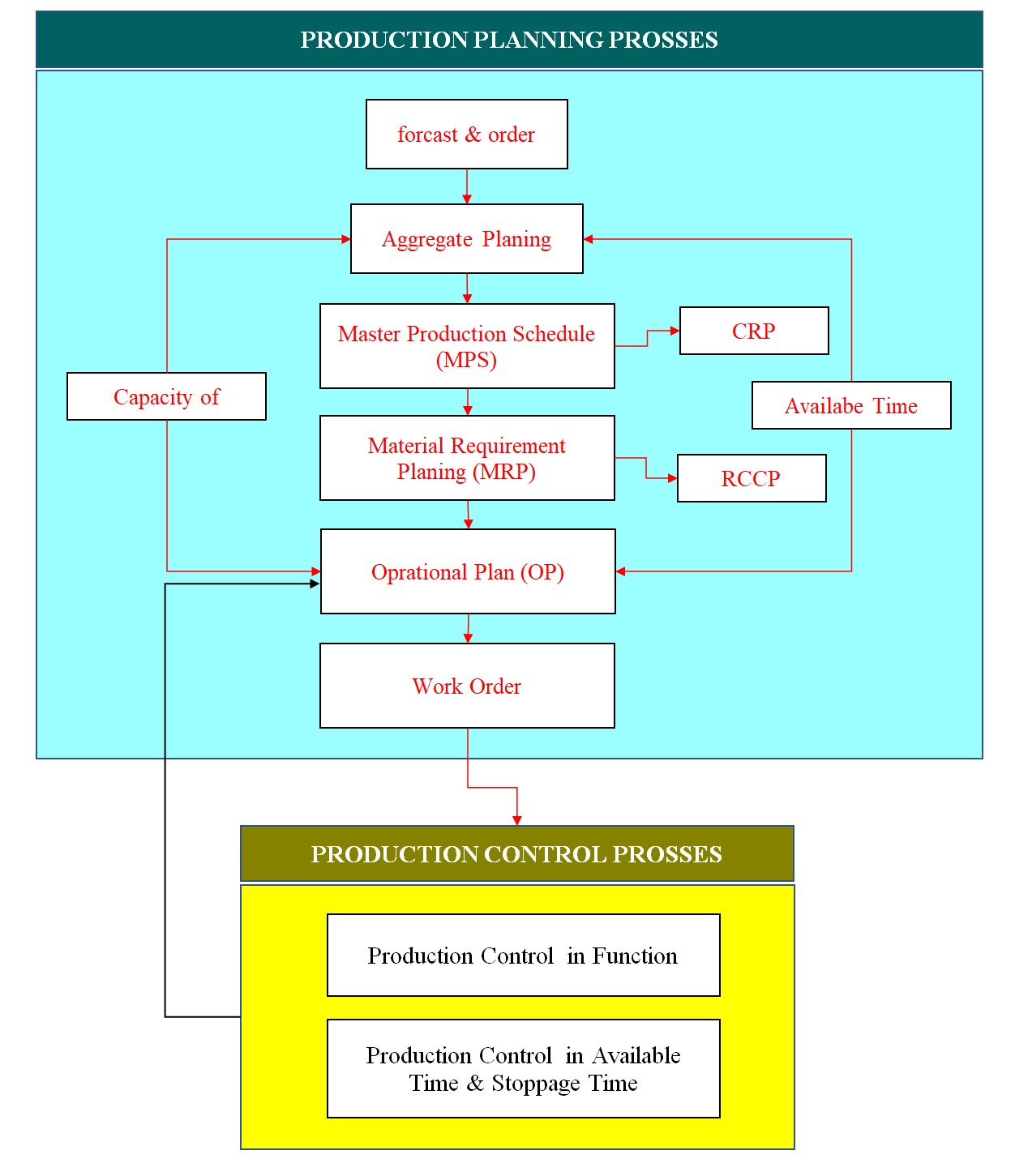

About production planning and control

Production planning represents the beating heart of any manufacturing process. Its purpose is to minimize production time and costs, efficiently organize the use of resources and maximize efficiency in the workplace. No manufacturing or service industry can be productive without a production plan. Effective planning is fundamental in any business. It's a complex process that covers a wide variety of activities that ensure that materials, equipment and human resources are available to complete the work. Production planning is like a roadmap to reach your destination. It helps you know where you are going and how long it will take you to get there.

Advantages of an effective production plan and scheduling is:

1. Reduces labor by eliminating wasted time and improving process flow.

2. Reduces inventory costs by reducing the need for safety stocks and excessive work-in-process inventories.

3. Optimizes equipment usage and maximizes capacity.

Although the production planning of the major tasks of production management, control summarizes its single most important issue. Process control has two purposes: first, to ensure that operations are performed according to plan and second, to continuously monitor and evaluate the production plan.

Define unlimited product line, product process, Production machine & Station, Materials , Components and Products

Defined types of shift and work calendar

Production Budget Plan

MPS & RCCP

MRP & CRP

Produce operational plans and work orders

Inserts work performance and stoppage

Reporting and estimate the efficiency of all workstations

Filling and reporting the latest status of contracts and production plans

Updated information of materials and components for use in production plans

defined unlimited user under network and determine access levels

Communicate with other information systems

Observe summary of management information